Nimbus cloud helps keep mines safe

Hundreds of open-pit mines exist in Australia. The stability of their pit walls can be a life-or-death issue for the on-site workers. A Curtin School of Mines doctoral candidate is working with Pawsey to reduce the risk of pit wall failure with a model that provides driller feedback in real-time.

The Challenge

There are over 390 open-pit mines operating within Australia, supplying the country with ores for domestic and overseas use. As the name suggests, open-pit mines extract ore from open pits dug into the earth.

A critical aspect of open-pit mining is ensuring the pit walls do not collapse. Wall failures have potentially fatal consequences. Fatalities as recent as 2021 have occurred due to pit failures such as pit wall and ground collapses. Since then, several incidents have resulted in injuries, damaged equipment and delayed operations.

On-site monitoring equipment collects data during drilling and blasting processes, to improve performance and maintain the safety of the mine site. Automated measurements are typically taken every few seconds using sensors. These sensors alert operators to changes in ground conditions. While data collection is straight-forward, experts also need a constant stream of condensed data results to make informed decisions about ongoing and future mining operations. Automated data analysis could give more frequent feedback, making excavation safer and cheaper.

Daniel Goldstein is a PhD candidate at the WA School of Mines at Curtin University. He is supervised by Professor Ernesto Villaescusa and Dr Danqi Li of WASM and Dr Quanxi Shao of CSIRO’s Data61. Daniel has created a model that can assess rock wall characteristics during drilling and provide real-time feedback to staff on-site.

“I’m a geotechnical engineer by trade. I’m concerned with the open pit mining environment, including pit wall formation and stability. I aimed to build a model that could take all the information about what is in the pit wall earth to tailor the blasting for the best outcomes in wall stability.”

The Solution

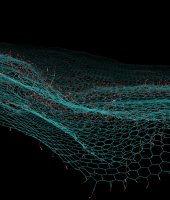

Daniel aims to apply his model to measure-while-drilling (MWD) processes. By tracking variables such as the pressure, speed and rate of bore drilling, MWD processes improve drilling into rock layers.

While MWD models already exist, most focus on the variables in isolation, rather than the effect they can have upon one another. This is an area Daniel wants to improve. A common example is the rate of penetration through earth while drilling (ROPED).

“The traditional logic has been that a stronger material will have a lower rate of penetration than a weaker material. Unfortunately, it is not as simple as that.”

Both the drill software and drillers aim to maintain an optimal rate of penetration, so they will adjust other drilling parameters to maintain that rate. This can interfere with monitoring software that uses the rate of penetration to make inferences about the nature of the drilled rock.

Daniel started his model on his personal computer. But as his data sets reached tens of thousands of points, he asked the Curtin Institute for Computation for resources to support the larger model. They recommended he work with Pawsey.

“The computation centre told me there was a valuable resource called the Pawsey Supercomputing Research Centre, in my own backyard, where I could apply for space on their Nimbus cloud. Because I’m still in the early stages of my research, my experiments are too big to do on a laptop, but not large enough that I need supercomputing. I’m in the sweet spot to use the Nimbus cloud.”

Daniel used Pawsey’s onboarding tools to become familiar with Linux and transfer his model to the Nimbus cloud. This included using both Pawsey’s technical support and user manuals.

“One bottleneck was that I had not used Linux systems before, so I had to learn that system. The support and documentation from Pawsey to get me set up have been phenomenal.”

The Outcome

The model will contribute to Daniel’s doctoral research, but it has the potential to be applied across the mining industry to improve the exploration of open pit mines and employee safety. If it the industry adopts it, Daniel’s model has the potential to reduce the risk of injuries and fatalities at open-pit mines. By being able to characterise earth composition more accurately whilst drilling, it could reduce operational expenses and save lives.

Partnering with Pawsey to use the Nimbus cloud saved Daniel tens of thousands of dollars in hardware costs to run his model. The cloud service was perfect for Daniel, at a point in his research he did not require a supercomputing allocation, but his work was still too computationally expensive for standard computers. It has the potential to make open-pit mines safer and cheaper to operate around Australia, as recognised by the Australian Geomechanics Society – Western Australia, which selected the research to receive the 2022 Dr Bayden Clegg Award.

Project Leader.

Drill and blast rigs (Open-pit iron-ore mine, Pilbara, Western Australia)

Geotechnical hazard predicted by machine learning analytical techniques from Measure-While-Drilling blast rig data (Open-pit coal mine, Bowen Basin, Queensland)