Characterization of coals and development of boiler combustion model for a supercritical boiler-2020

- Optimisation and improvement of a working coal fired boiler, undergone with some CFD aids involvement. - Coal burning power plants spread around the world and are one the worse alternatives, with respect to environmental aspects. - Economically, coal is ways cheaper than other energy resources, per unit of energy. Therefore, it is too difficult to convince all industries and governments to stop burning coal. - The main goal is to minimize the stack contaminants by improving operational conditions, to make coal burning boilers, less harmful for environment

Area of science

Engineering

Systems used

Magnus, Zeus and Topaz

Applications used

Ansys FluentThe Challenge

To provide a better understanding of the coal combustion in the coal burning boilers, aiming to reduce air pollutants and greenhouse gases emitted from the stack.

The Solution

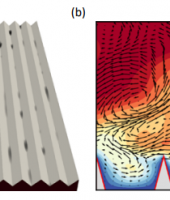

Using a CFD model to have a better understanding of the combustion and heat transfer and use the information to improve operation strategy.

The Outcome

The complex nature of the problem, which includes mass transfer, heat transfer, particle-based combustion, surface and particle radiation, and various pollutant generation/elimination reactions, would result to a very computational demanding CDF model. Without the resources Pawsey had allocated to the project, it was impossible to develop and validate the model, use it for different scenarios or post-process the results.