High-fidelity simulations of turbomachinery applications

The long-term objective of this high-fidelity simulation program is to generate the fundamental understanding and low-order design tools required to develop the next generation of efficient and environmentally friendly turbines for power generation and air transport. Overall, our research team is focused on shedding light on the fundamental physical mechanisms of the complex flow fields and the most significant loss generation mechanisms inside of gas turbines, how to further improve turbine cooling and identifying and addressing noise generation mechanisms of wind turbine blades. In 2021, high-fidelity simulations have been conducted of fluid flows occurring in turbomachinery applications with an in-house code specifically designed and optimised to exploit the performance of supercomputers. We have conducted simulations at realistic engine conditions, giving us unprecedented understanding of the physical phenomena occurring in these flows. The data is used to help assess the current low-order models that are employed in an industrial environment. The data also serves as gold-standard database for developing new and improved models based on machine-learning approaches.

Area of science

Engineering

Systems used

Magnus, Zeus and Topaz

Applications used

HiPSTAR and some OpenFOAMThe Challenge

Australia relies heavily on gas turbines (GTs) for propulsion- and power-generation. Given the very large installed base nationally, and worldwide, any GT efficiency increase has significant potential to reduce fuel burn and environmental impact. One of the keys to improving the operating efficiency of GTs is the ability to understand and predict the detailed flow behaviour inside of the engine. The challenge is that the flow inside an engine is mostly turbulent, and turbulence is a highly chaotic process, featuring a large range of scales, that is extremely hard to predict. Today’s design of gas turbines is driven largely by computational fluid dynamic (CFD) modelling. However, some of these turbulence models are really only accurate in “known” situations, where the flow behaviour is well recognised, and the models have already been calibrated. If off-design conditions or more radical novel concepts are to be considered, these models cannot be trusted. In addition, the accurate prediction of the turbulent heat transfer is a key design consideration for ensuring survival of key turbine components and hence reliability of turbines. This research also aims to improve heat transfer models that are even less reliable and mature than current turbulence models.

The Solution

To avoid model uncertainty, the governing equations of fluid flow can be solved directly in so-called direct numerical simulations that resolve all scales of turbulence without assumptions. To resolve all the scales of turbulence, from large to small eddies, requires extremely large and costly simulations, with the number of unknowns exceeding 1,000 trillion values. However, the reward for performing these very large simulations is that a detailed and reliable representation of the flow and heat transfer inside an engine can be obtained. The data can then be used to gain new insight into fundamental physical mechanisms and to assess and develop new models. Prof Sandberg’s group at the University of Melbourne has developed a cutting-edge flow solver optimized for efficient use of modern high-performance computers that is one of the prerequisites for conducting direct numerical simulations of gas turbine flows.

The Outcome

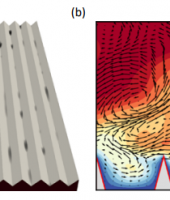

Model-free direct numerical simulations of turbulent flow and heat transfer with relevance to gas turbines are only possible on very large supercomputers. The access to Magnus has allowed us to conduct a range of high-fidelity simulations that would not have been possible on local resources. Various cases have been studied, from looking at loss mechanisms in high-pressure turbines, in particular the effect of inflow perturbations and/or Mach number variations on loss generation, the complex flow fields that are occurring inside compressor cooling systems, the heat transfer of turbulent pulsed jets impinging onto a surface, to evaluation of how flexibility of serrated trailing edges can be used to reduce noise generation of airfoils.

Commercial Advantage of this Project

A large fraction of our work is performed in collaboration with industry partners, mainly GE Aviation and MHI. However, it is very hard for us to estimate what the commercial value is they have been able to derive from the simulation results we have reported to them.

List of Publications

Journal Papers:

Lav, C., Sandberg, R.D., Tanimoto, K., Terakado, K., 2021, “Momentum boundary-layer characterisation from a pulsed impinging jet,” accepted for publication in Int J. Heat Fluid Flow 08/12/2021.

Sandberg, R.D., Michelassi, V. 2021, “Fluid Dynamics of Axial Turbomachinery: Blade- and Stage-Level Simulations and Models”, Annual Review of Fluid Mechanics, 54.

Akolekar, H., Waschkowski, F., Zhao, Y., Pacciani, R., Sandberg, R.D., 2021, “Transition Modeling for Low Pressure Turbines Using Computational Fluid Dynamics Driven Machine Learning”, Energies, 14, 4680.

Akolekar, H., Zhao, Y., Sandberg R.D., Pacciani, R., 2021 “Integration of Machine-Learning and Computational Fluid Dynamics to Develop Turbulence Models for Improved Low-pressure Turbine-Wake Mixing Prediction”, Journal of Turbomachinery, 143(12), p.121001.

Zhao, Y., Sandberg R.D., 2021 “High-fidelity Simulations of a High-pressure Turbine Vane: Effect of Exit Mach Number on Losses”, Journal of Turbomachinery, 143(9): 091002.

Saini, D., Sandberg R.D., 2021 “Large Eddy Simulations of High Rossby Number Flow in the High-Pressure Compressor Inter-Disk Cavity”, Journal of Turbomachinery, 143(11), p.111002.

Otero-Perez, J., Sandberg R.D., Mizukami, S., Tanimoto, K., 2021 “High-Fidelity Simulations of Multi-Jet Impingement Cooling Flows”, Journal of Turbomachinery, 143(8): 081011.

Wu, H., Sandberg, R.D., Moreau, S., 2021, “Stability characteristics of different aerofoil flows at Rec = 150,000 and the implications for aerofoil self-noise,” Journal of Sound and Vibration, Vol 506, p.116152.

Lav, C., Haghiri, A., Sandberg, R.D., 2021 “RANS predictions of trailing-edge slot flows using heat-flux closures developed with CFD-driven machine learning“ Journal of the Global Power and Propulsion Society, 2021(May), pp.1-13.

Peer-reviewed Conference proceedings:

Leggett, J., Zhao, Y., Richardson, E., Sandberg R.D., 2021 “Turbomachinery loss analysis: the relationship between mechanical work potential and entropy analyses”, ASME IGTI, GT2021-59436.

Leggett, J., Sandberg R.D., 2021 “Highly resolved simulations of a CDA compressor cascade: effect of Reynolds number on losses”, ASME IGTI, GT2021-58665.

Lav, C., Sandberg R.D., 2020 “Unsteady simulations of a trailing-edge slot using machine-learnt turbulence stress and heat flux closures.”, ASME IGTI, GT2021-14398

Figure 1. Re100k_TR08_Moment.jpg: Turbulent pulsed jets with high temperature migrating towards impingement wall.